Understanding Turing Patterns in Soft Robotics

Fabric-based soft pneumatic actuators (FSPAs) are innovative devices that leverage Turing patterns to enhance their design and functionality. These are soft and flexible devices capable of deforming or moving by inflating or deflating. They are commonly used in soft robotics due to their ability to safely interact with humans and delicate objects.

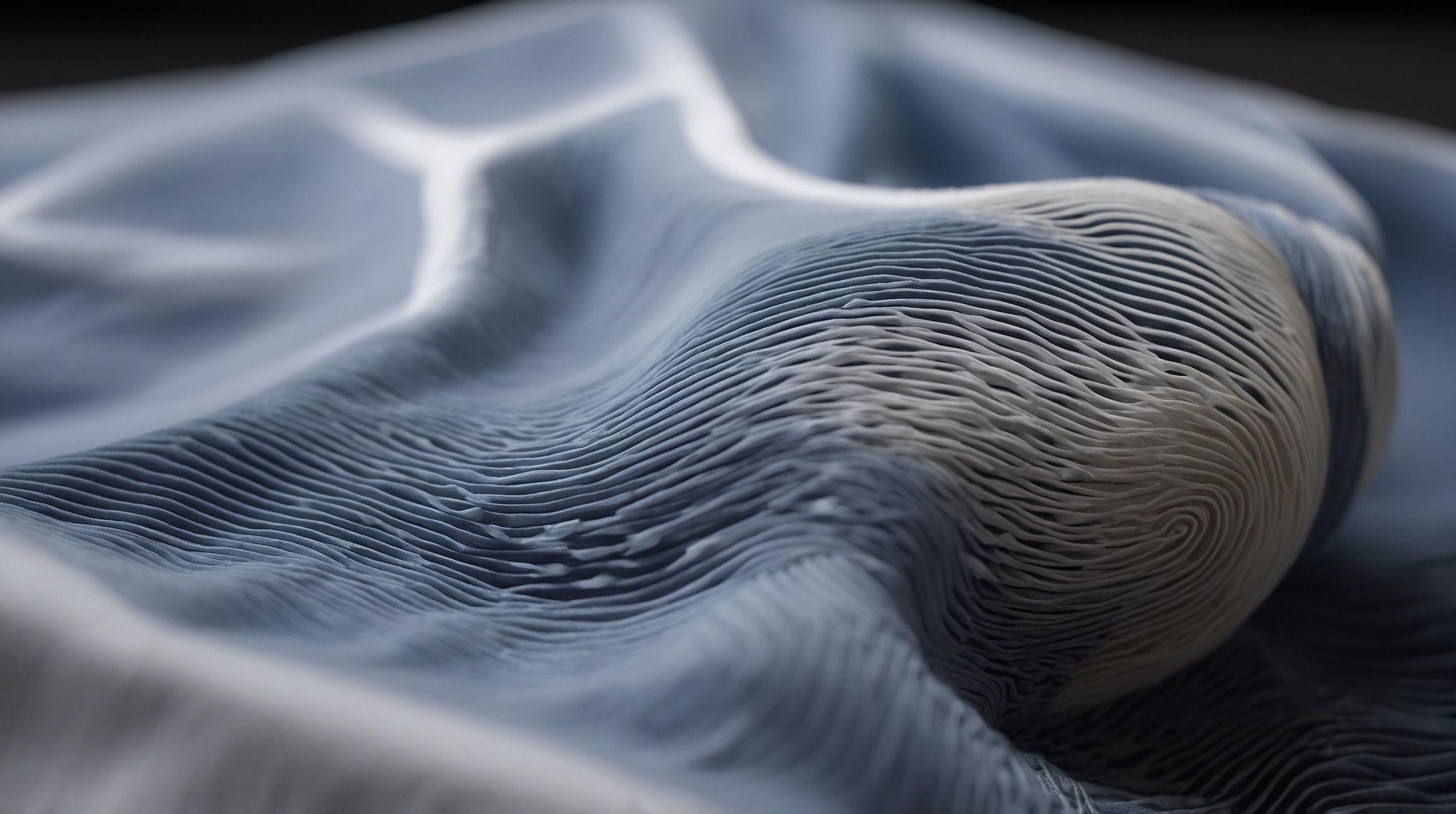

The Role of Turing Patterns

Alan Turing's concept of morphogenesis, which describes natural pattern formations like stripes and spirals, is crucial here. Turing patterns emerge in systems with reaction and diffusion components. Imagine two substances interacting: one promotes growth, while the other inhibits it. This balance results in stable, repeating patterns, such as zebra stripes.

Automating the Design Process

Designing these actuators traditionally involved a lot of trial and error to find the right material properties. Researchers, including Dr. Masato Tanaka and his team, have automated this process by optimizing the orientation of fibers in the fabric. They use a gradient-based orientation optimization method, which is a mathematical approach to arrange fibers for desired movement. They incorporate anisotropic materials, which means materials that have different properties in different directions, to achieve this.

Fabrication Techniques

The team explored two main methods: heat bonding and embroidery. Heat bonding involves laser-cutting a rigid fabric into the Turing pattern and attaching it to a softer fabric, while embroidery uses stiff thread to create regions of varying stiffness. Both methods are scalable and cost-effective.

Comparing with Traditional Designs

The research showed that Turing pattern designs often outperform classical designs. For instance, their C-shaped designs reduced the distance between actuator edges by 10% compared to traditional approaches.

Future Applications and Research

The team envisions integrating Turing patterns with advanced materials like shape memory polymers for better dynamics. They also aim to scale up production using techniques like 3D printing with flexible materials, enhancing efficiency and precision.