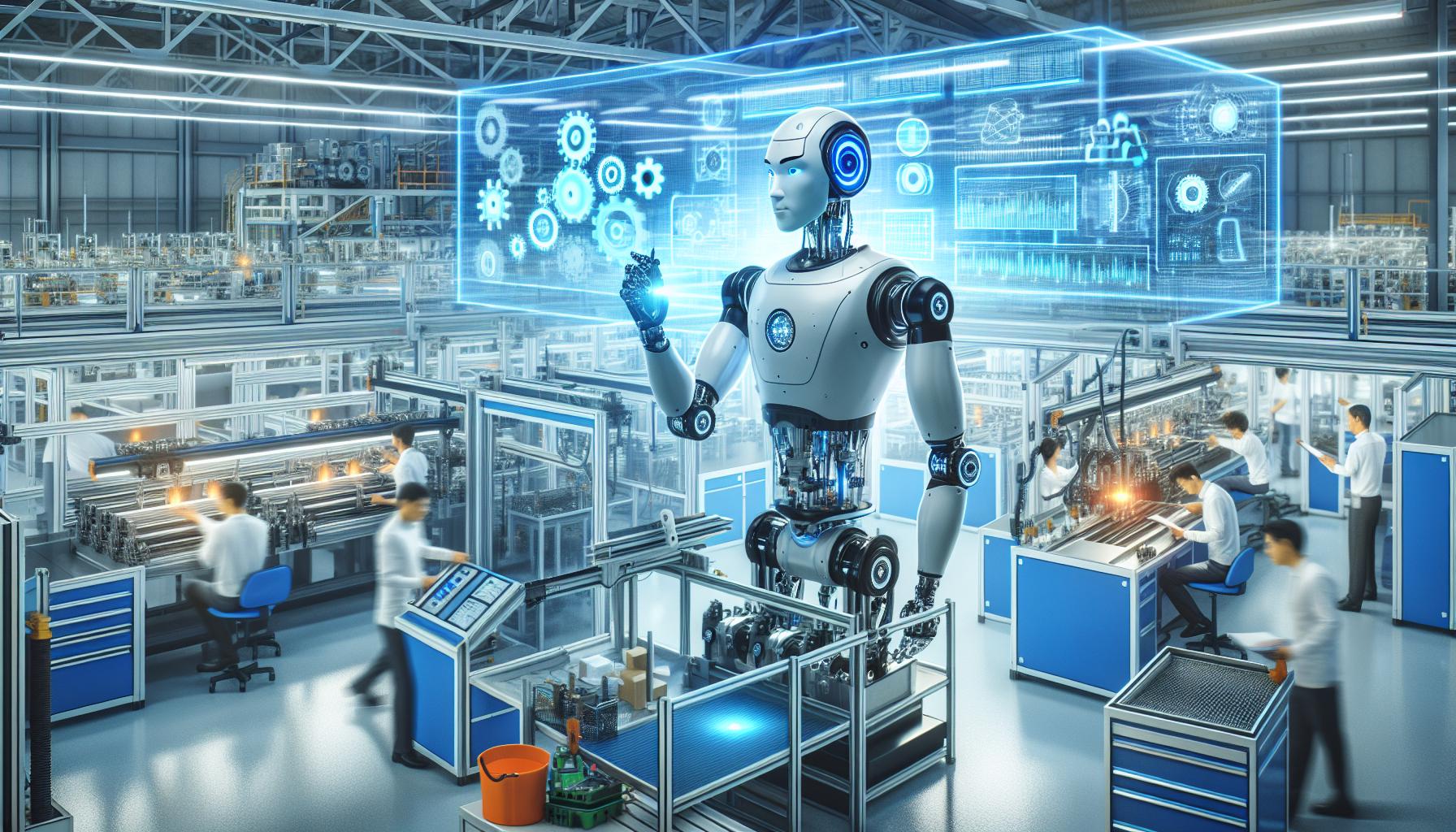

World’s First AI Technology for Robot Work in Manufacturing Processes

A groundbreaking AI (artificial intelligence) technology has been developed, enabling robots to easily take on various tasks in manufacturing processes. This achievement, a world first, has the potential to revolutionize the manufacturing industry by improving efficiency and enhancing the working environment at manufacturing sites.

The technology was developed by a research team led by Chang-hyun Kim, head of the Department of AI Machinery at the Korea Institute of Machinery and Materials (KIMM). This AI technology for robot work can be applied to a range of manufacturing processes, including the production of automobiles, machine parts, assembly, and more.

Advancements in AI Technology Enhance Manufacturing Environments

The newly developed AI technology is already being applied to the manufacturing processes of electronic component producers, with plans to expand its application to other manufacturers in the future. This technology is based on the “Large Language Model (LLM)” and virtual environment, allowing robots to understand user commands, generate task commands, and execute them automatically.

By using this technology, task sequences and movements can be generated via voice or text commands, reducing the need for manual programming. Additionally, pre-learning in a virtual space enables the selection of an optimal work point and helps to minimize the work process, detect objects, and avoid collisions.

Integrating AI and Robotics to Improve Manufacturing Efficiency

Traditionally, manufacturing sites have had to modify their environments to accommodate robots, limiting the tasks that robots can perform. Furthermore, the integration of different technologies required for specific tasks, such as movement and recognition, has been a challenge.

The combination of AI technologies like LLM with robotics opens up new possibilities for automating various tasks. The breakthrough AI technology developed by the KIMM allows for easy specification of tasks for robots and minimizes on-site modifications. This integration of AI and robotics has the potential to significantly improve manufacturing efficiency.

How AI Technology is Revolutionizing Manufacturing Processes

The newly developed AI technology for robot work is a game-changer for the manufacturing industry. It allows for the automation of complex tasks, reduces the need for manual programming, and enhances the flexibility and adaptability of robots in manufacturing environments.

With the ability to generate task sequences and movements based on voice or text commands, robots can quickly adapt to changing manufacturing requirements. The pre-learning process in a virtual space further improves efficiency by selecting the optimal work point and minimizing the risk of collisions.

The Future of Manufacturing: AI and Robots Take Center Stage

The development of this AI technology for robot work marks a significant milestone in the evolution of manufacturing processes. As on-site demonstration tests are currently being conducted, it is clear that AI and robots will play an increasingly active role in the manufacturing industry.

The application of AI in manufacturing processes will lead to greater efficiency, higher productivity, and improved working conditions. The integration of AI and robotics will enable manufacturers to streamline operations, automate repetitive tasks, and focus on more value-added activities.

In conclusion, the world’s first AI technology for robot work in manufacturing processes has been successfully developed, paving the way for a new era of automation in the manufacturing industry. With advancements in AI technology and the integration of robotics, the future of manufacturing looks promising, with increased efficiency and improved working environments at manufacturing sites.

Analyst comment

Positive news: The world’s first AI technology for robot work in manufacturing processes has been developed, revolutionizing the industry by improving efficiency and enhancing the working environment. This breakthrough technology allows for automation of complex tasks, reduces manual programming, and enhances the flexibility and adaptability of robots. The integration of AI and robotics has the potential to significantly improve manufacturing efficiency. Analyst prediction: The market for AI technology in manufacturing will experience growth as more companies adopt this revolutionary technology to streamline operations, automate tasks, and improve productivity. Manufacturers will see increased efficiency and improved working conditions, leading to potential market expansion in the future.