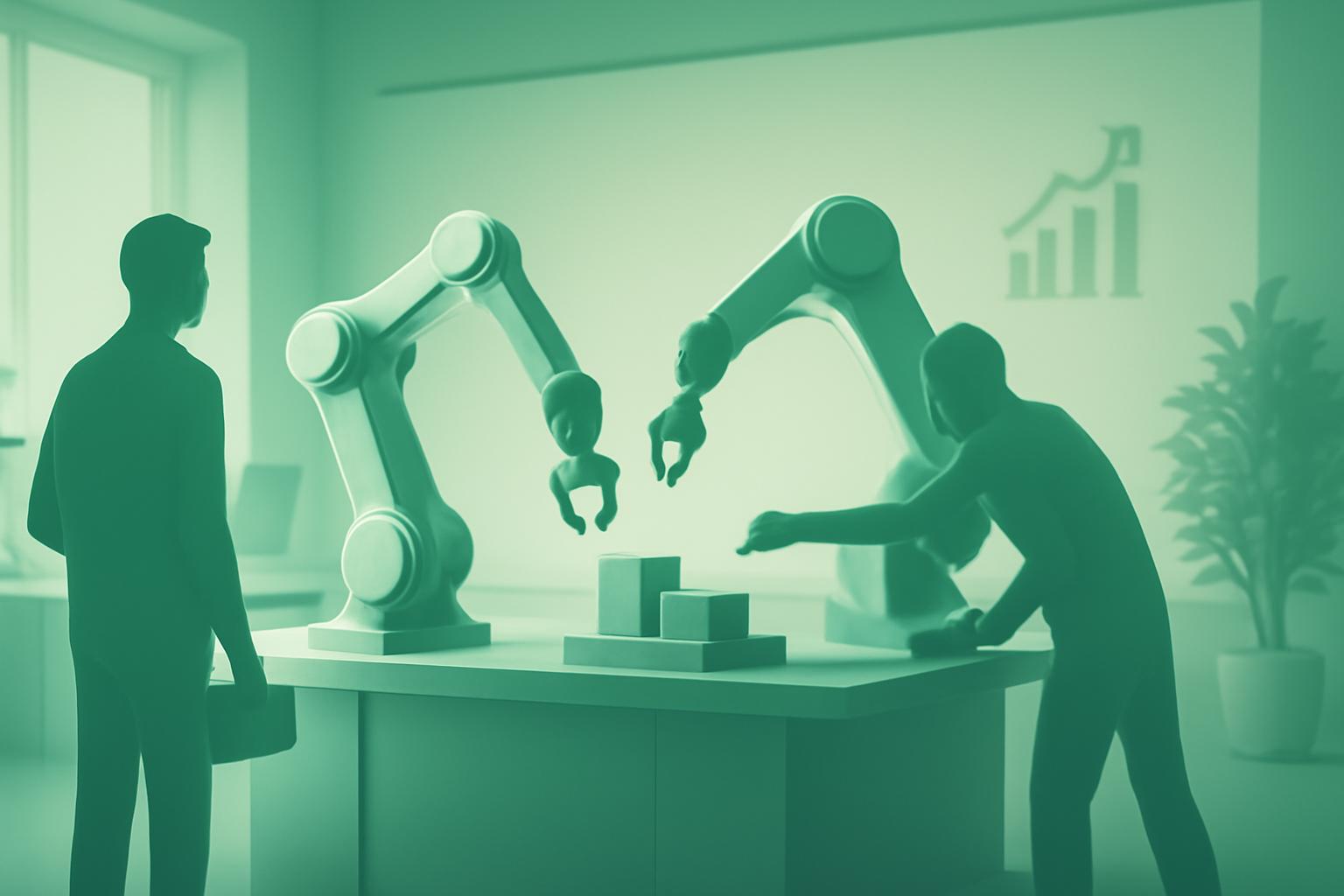

San Francisco Startup Develops Compact AI-Powered Robotic Factory

MicroFactory, a San Francisco-based startup, is redefining automation by creating a compact, general-purpose robotic manufacturing system roughly the size of a dog crate. Unlike many robotics firms focusing on human-sized robots or large-scale factory automation, MicroFactory’s tabletop solution integrates two robotic arms capable of learning tasks by watching humans and through artificial intelligence.

Human Demonstration as Core Training Method

Co-founder and CEO Igor Kulakov emphasized that their robots are designed to be general purpose but intentionally non-humanoid, simplifying both hardware and AI development. The enclosed, transparent workstation enables users to observe manufacturing processes in real time. Precision tasks such as circuit board assembly, component soldering, and cable routing are key applications.

Training involves physically guiding the robotic arms through complex movements, a hands-on approach that Kulakov argues is faster and more effective than traditional AI programming for intricate manufacturing sequences. “Usually it takes a couple hours, but in this way, the robot much better understands what it should do,” Kulakov explained.

Founders’ Manufacturing Experience Drives Innovation

Kulakov and co-founder Viktor Petrenko drew on their experience running bitLighter, a manufacturing business producing portable lighting for photographers. Frustrated by the extensive training required for new employees, they saw an opportunity to use AI to automate manufacturing tasks. MicroFactory was founded in 2024 and developed its prototype in approximately five months.

Strong Early Demand and Funding

The startup has already received hundreds of preorders for diverse uses, including electronics assembly and even processing snails for culinary export. Recently, MicroFactory closed a $1.5 million pre-seed funding round featuring participation from executives at AI company Hugging Face and investor Naval Ravikant. This round values the company at $30 million post-money.

Future Plans and Scaling Production

MicroFactory aims to transition its prototype into a commercial product and begin shipping within two months. The company plans to ramp up production to approximately 1,000 units in its first year, averaging three units per day. Additional hires and ongoing AI improvements are also priorities.

“Our growth is related to building hardware, so we set the goal to increase it 10x each year,” Kulakov stated. “In the first year, we want to produce 1,000 robots, and we have the capability to do this. Then, [we want to] make more and more productions.”

FinOracleAI — Market View

MicroFactory’s novel approach to compact, human-guided robotic manufacturing presents a promising innovation in automation, particularly for small-scale precision tasks. The early preorders and $1.5 million funding round backed by prominent investors signal strong market interest. However, scaling production from prototype to mass manufacturing poses execution risks, including hardware reliability and software robustness.

Impact: positive